Yesterday morning had us headed about 2.5 hours northwest from Hyderabad to a small village called Bidar. This area is famous for a unique metalware comprised of zinc, copper and inlaid silver called Bidriware. It originated in Persia and came to India over 500 years ago.

There are only 6 companies making Bidriware so it's a very specialized craft. The artists work as a team to complete each piece, organized in a casual assembly line. These men are all specialists in what they do, and there are only 180 in the entire country trained in this handicraft.

It all starts with a block comprised of 80% zinc and 20% copper, and it takes 8 steps to complete each piece of Bidriware. We followed the entire process, from raw pieces of metal all the way to the finished product - a beautiful elephant. The 4" elephant took 4 hours to make and included at least 5 craftsmen: molding, design, engraving, inlay, and finishing.

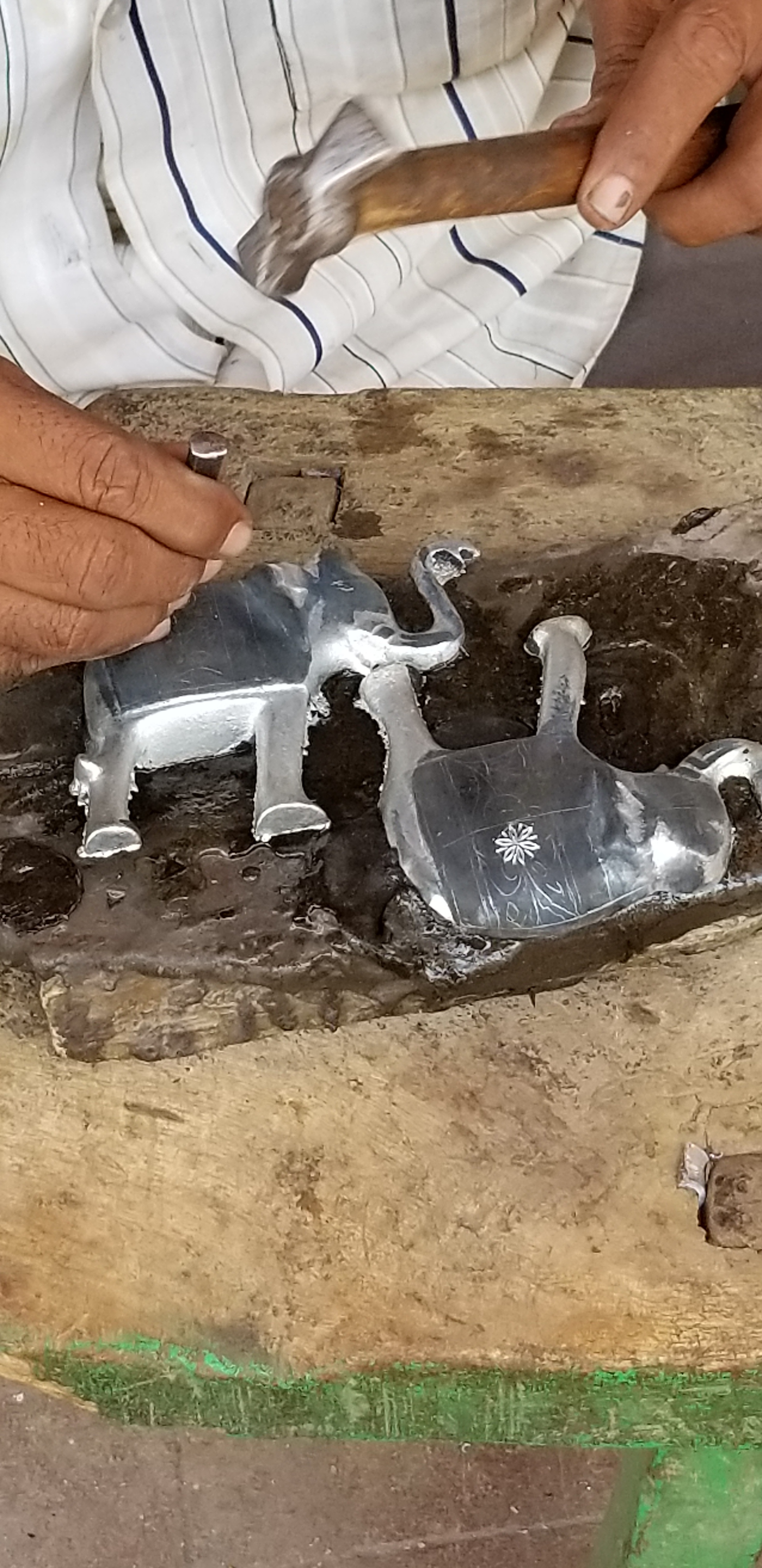

From this block the general structure is formed through a process of melting down the block and pouring it into the desired mold. The mold is packed with local black soil soured from an ancient fort in Bidar and is said to have special properties integral to making Bidriware. I'm still not sure what makes the soil so special but every single craftsmen will tell you it's an important part of the process.

After tamping it down so the impressions are defined, the molder then creates channels so when he pours the molten zinc/copper mix, it will fill in the desired area.

After a few minutes of cooling time, 'et voilà'! The first step is complete!

Next the elephant was filed and sanded so no rough edges remained. After that, ammonium chloride is used to oxidize the zinc. This is done at this stage so the engraver can see his design as he etches it.

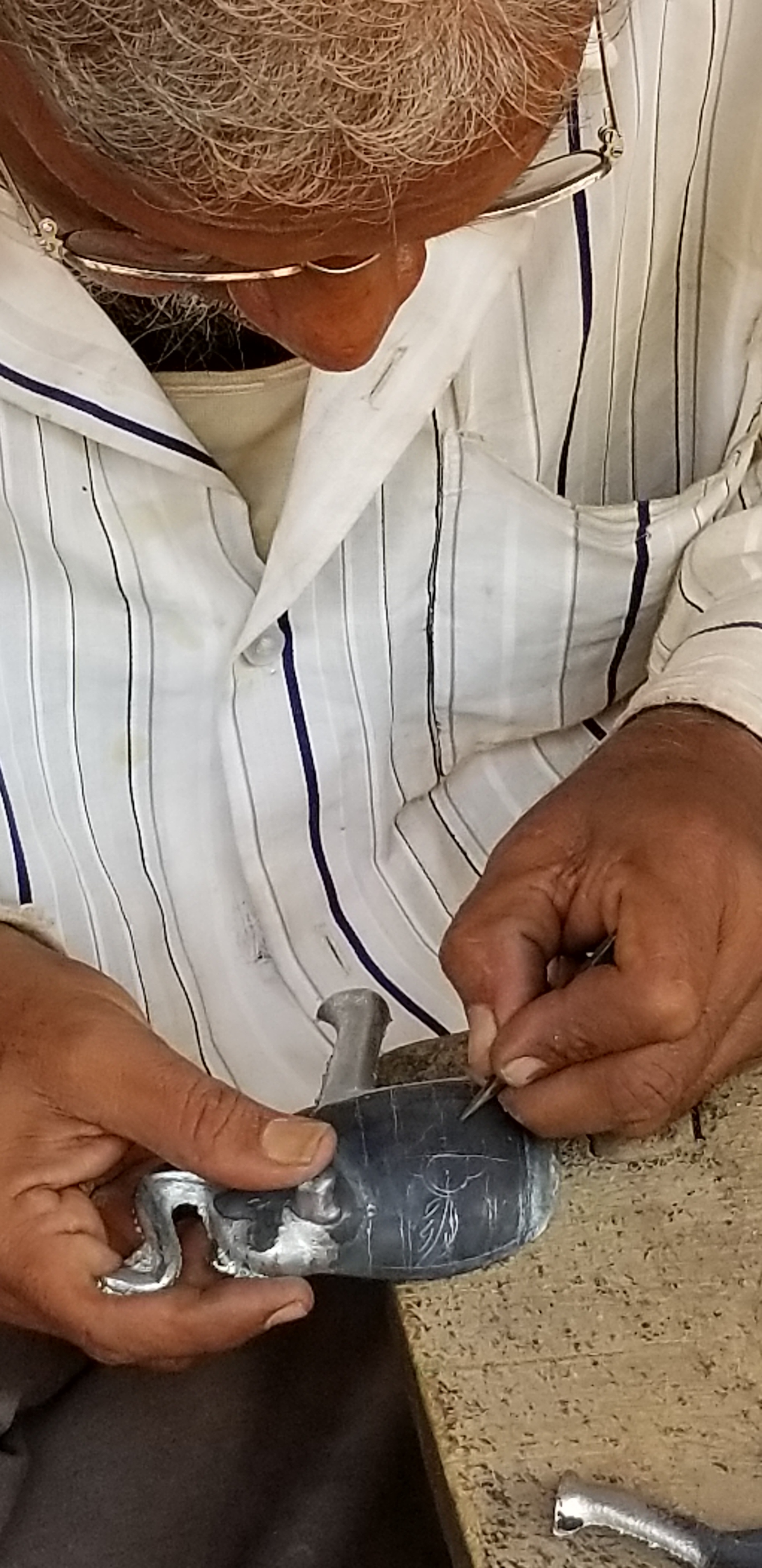

Next the mold is applied to a wax covered portable workbench of sorts. This keeps the pieces stationary as they are worked on by each artisan. The master designer takes it back and starts doing the deep etching that will become channels for inlaid silver.

And now the inlay pro joins in. First he files down the silver wire to be the appropriate gauge for this project.

After the gauge is perfected, he heats the wire so it's more malleable and begins to hammer the wire into the design.

After all the silver inlaying is completed, he passes the elephant back to be taken off the wax board and filed again. The "finisher" files until the seams are smooth and then solders the two sides together with a mixture of zinc, tin, and lead.

Ta da! A fully assembled elephant! The elephant now gets filed again and buffed all over...again. Even the oxidization gets buffed off at this stage to ensure a uniformly smooth surface.

Next the poor dear gets cleaned off with kerosene and then placed into ash to absorb the kerosene until she is completely dry.

Now for what the craftsmen called "original magic." The finisher takes a bag of local dirt, tastes it for purity (I'm not kidding) and then mixes it with water and ammonium chloride. He then heats the mixture until boiling. And then this happens:

Yes, this baby took 4 hours to complete but boy was that a satisfying way to end the process! After she comes out of the goo, she gets polished up with coconut oil and now this beautiful piece of art exists in the world.

Because of the materials used and the process being so labor intensive, Bidriware is highly prized and somewhat expensive. It's often given as diplomatic gifts (Obama received a Bidriware samovar on a state visit) and the artists take great pride in their workmanship. The team we spent the day with had recently been awarded first place in a local competition for their work.

I really marvel at what goes into making every single piece. There is no automation involved and no shortcuts taken. I love seeing this ancient process live on with new generations. If you have the opportunity to collect a piece, you should. After a hard days work, I got to take home the elephant.